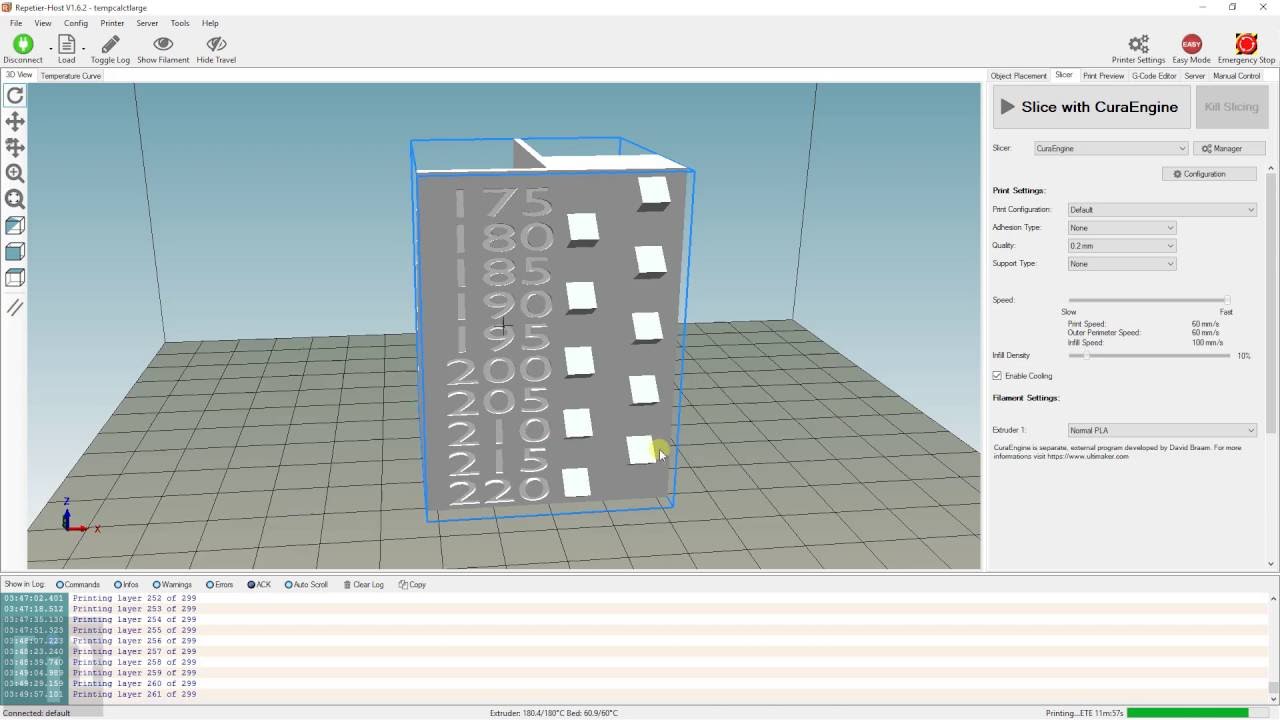

I want to know if I understand the different parts of a 3d printer. So please chime in if you have some spare time :)Frame – Holds everything together.Enclosures – These are used to keep temperature swings (and the resulting lifting, warping) to a minimum for materials such as ABS.Stepper Motors – X,Y,Z (sometimes 2 Z if a corexy) control the linear motion of the extruder/hot-end and bed via Threaded rods.Threaded rods – Used in concert with lead screws and couplings to move some the parts around. (smooth rods for rail travel)Belts – used in conjunction with Stepper motors to facilitate certain movements along smooth rods.Hot-end – Where the filament comes out. The hotter the hot end can get the more “exotic” the filament. The harder the hot-end, the more abrasive the filament can be and/or less prone to wear.Extruder – channels the filament from the spool (or source) to the hot-end with a gear drive. Cheap gears can strip and clog.Fans – (obvious) but important for proper cooling.Bed Plate – This is what most print surface beds sit on with screws and springs attached and are adjusted from with thumbwheels etc to level.Print Surface Bed – Can be heated (usually is in 2016), the temp is dictated by the filament used and also the heat bed surface properties.Control box – (optional) houses the power supply and the control board, LCD, knobs etc. The parts do not have to be in a “box”.Control Board – Usually (or always?) an Arduino type board (not sure). What board depends on what capabilities the printer requires. Cheaper usually = less.Stepper Drivers – These are little electronics boards in addition to the control board (unless purchased with it) and come in different types. (These are soldered onto the board?) If you want to control more stepper motors, you’d need an equal number of drivers.Firmware for the Control Board – Usually Marlin, Sailfish or Repetier-Firmware, these are loaded onto the control board and can be replaced as one see’s fit so long as the board has enough memory.SD or USB connection – this is how the g-code files are stored/read by the FirmwareG-Code – this is line by line set of instructions that controls every aspect of the printer, it is a user editable file but usually done via a slicer.If I have anything wrong, please let me know, or if I missed any important part of the process. I want to go through each one to learn the ins and outs of each so I have a firm grasp on the parts and processes. I am slightly ignorant of how the extruder and hot end work together. I get it, but there is more to my idea of hot it works, for example, talk about PETG tubing being only able to handle 260 or something-something, not sure where or when that comes into play?I have been reading a lot and getting a bit confused on the various names of firmware, boards etc.. It’s a bit overwhelming.Eventually, I want to build my own printer but I want to know everything first. Like say I want to add automatic bed leveling, I’d need a probe, therefore I’d need to understand where to disconnect the end stop and how to adjust the firmware or and/g-code. I have purchased an Original Prusa Mk2 in kit form so that will get me started with the actual physical parts and how they go together. But eventually, I will want to build something with the best board, firmware, extruder, hot end etc..So, do I understand or am I missing some crucial items to research? http://ift.tt/2dbtZjX